Electric Arc Welding Safety Training

Arc Welding – Safety and Technique

Electric Arc Welding is a vital industrial process which makes it possible for us to fuse two separate pieces of metal together into one solid mass. The principle is the same as when you take the exposed wires from the positive and negative terminals of a fully charged battery and touch them together, and we all know what happens then: A Spark.

In Arc Welding, this ‘spark’ between oppositely charged poles is maintained, and becomes an ‘electric arc’ which generates tremendous heat: Up to 6,000°C at the point of contact between the poles.

This raises the temperature of the metals to the point at which welding can occur.

About the course:

The objective of the electric arc welding safety training program is to highlight the importance of operating Arc Welding equipment safely as well as to demonstrate the correct and safe way to perform some of the most common welds.

The program shows correct and safe techniques as well as equipment knowledge and includes:

- Explanation of the Arc Welding Process and how it works

- Arc Welding Safety Equipment

- Personal Safety

- ‘Arc’ or ‘Welders’ Flash

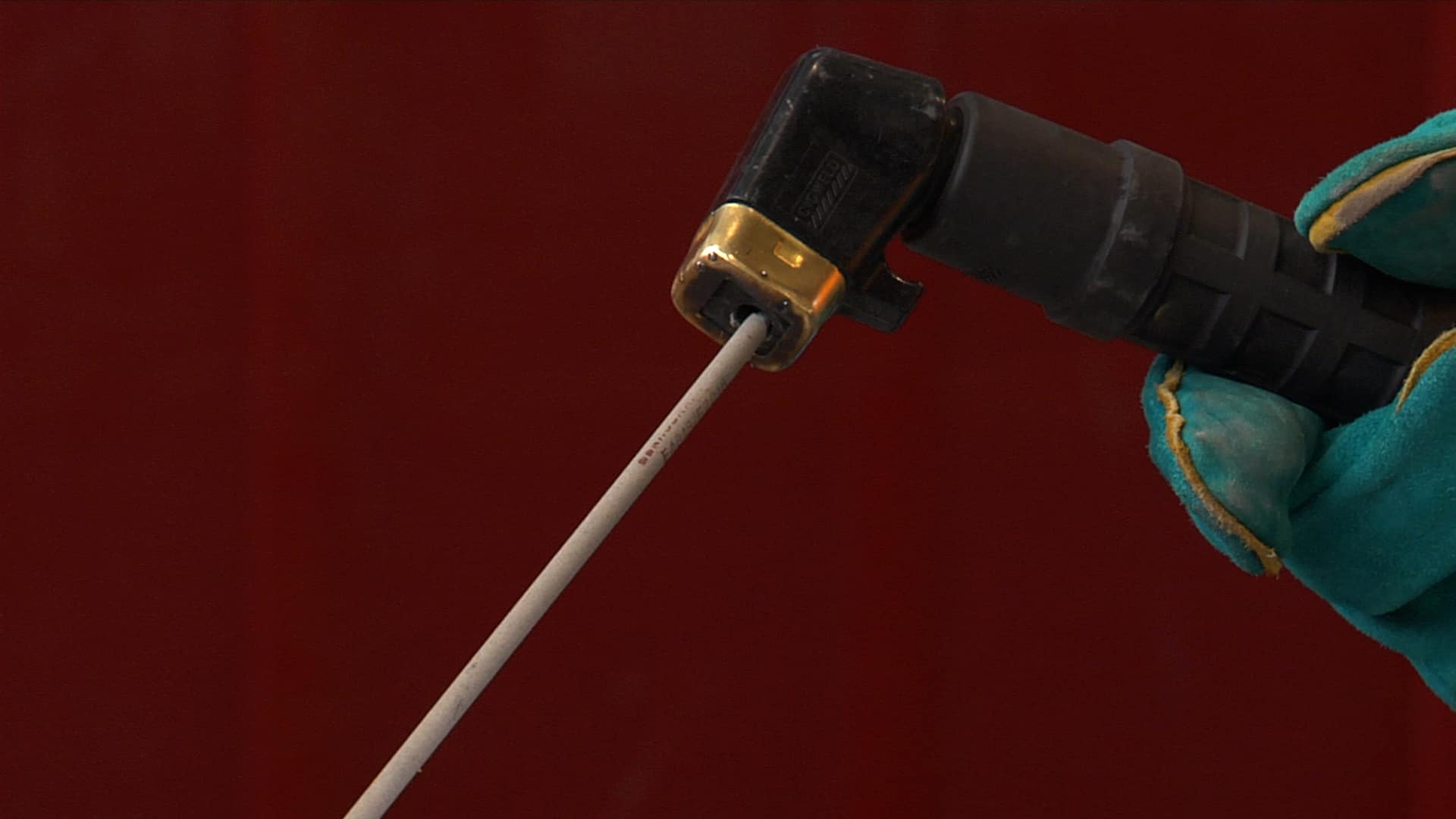

Striking the Arc:

- Making a Weld Run

- Welding Faults – How they occur and how to prevent them

Correct procedures for a variety of Welds including:

- Tack Welding

- Square Edge Butt Joint

- Fillet Weld

- Outside Corner joint

- Lap Joint Weld

- Single V-Butt

- The Weaving Technique

Video Running Time:

23 minutes