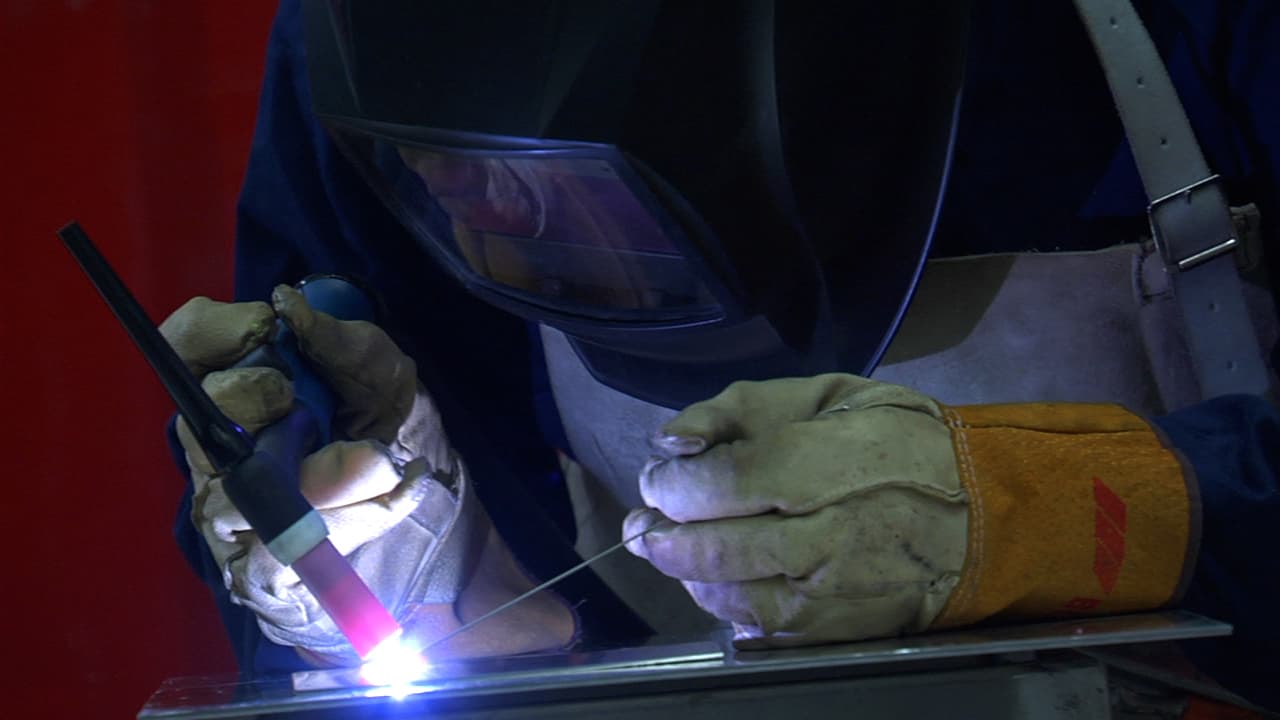

TIG Welding Safety Training

Safety and Technique

The TIG Welding Process produces extremely high temperatures which permits pinpoint control of heat over a small heat affected zone. TIG welding is widely used when fine, high quality welding is required, particularly when welding metals such as aluminium and stainless steel.

TIG Welding Safety Video:

The objective of this program is to highlight the importance of operating TIG Welding equipment safely as well as to demonstrate the correct and safe way to perform some of the most common welds.

This program covers a wide range of aspects relating to TIG welding and includes:

- The advantages of the TIG welding process

- Understanding the TIG process

- TIG welding equipment

The types of welding current available for TIG welding:

- Direct current straight polarity

- Direct current reverse polarity

- Alternating current

- Understanding the high frequency application

- Torches and Electrodes

- Weld contamination

- Shielding gases

- Workshop and personal safety

- Setting up to weld

TIG welding examples:

- Edge weld without filler rod

- Corner weld

- Lap joint weld

- Tee fillet weld

- Butt welds

- Closing down the TIG unit